The Difference Between CAD, CAM, and CAE Explained Simply

Last Updated on 2025-03-20

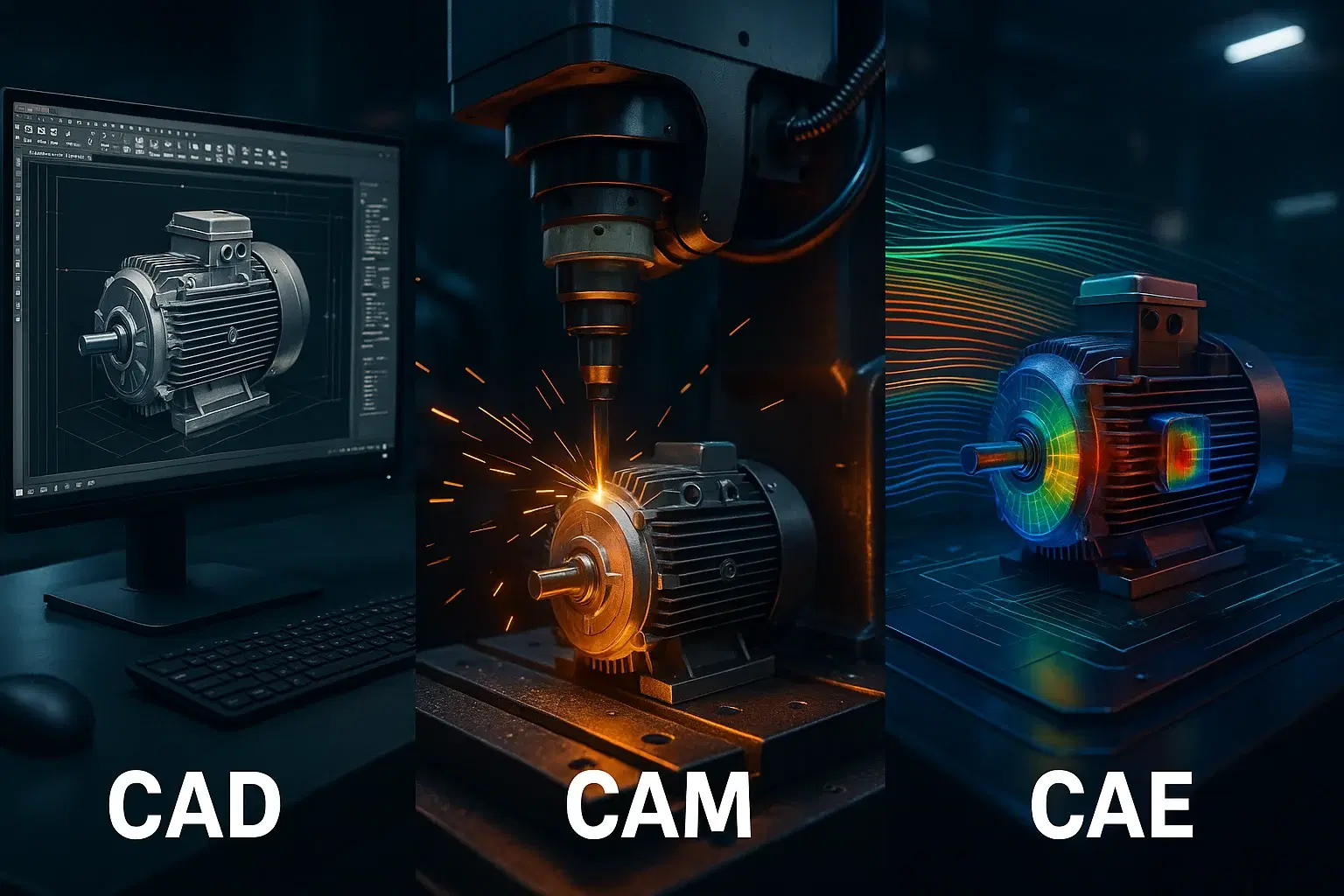

In the rapidly evolving world of engineering and manufacturing, terms like CAD, CAM, and CAE are everywhere—but do we really understand how they shape the way products come to life? While all three rely on **computer-aided technologies, each plays a distinct role in design, production, and innovation. Understanding these differences isn’t just technical—it’s strategic.

What is CAD? (Computer-Aided Design)

Imagine designing a complex machine without a single mistake or wasted material. That’s the promise of CAD software. Engineers, architects, and designers use CAD to create precise 2D and 3D digital models of products and components.

Key Uses of CAD:

- Visualizing ideas before they exist

- Drafting accurate technical drawings

- Validating designs virtually to prevent costly errors

- Collaborating seamlessly across teams

Popular tools like AutoCAD, SolidWorks, and CATIA make this possible. But here’s the deeper question: Could our designs ever truly surpass human imagination without digital tools?

For those looking to expand their abilities, CAD courses offer more than technical skills—they provide a lens to rethink what’s possible in design and innovation.

What is CAM? (Computer-Aided Manufacturing)

While CAD is about ideas, CAM software is about reality. It turns digital designs into instructions for CNC machines and other manufacturing tools, ensuring precision, efficiency, and repeatability.

Key Uses of CAM:

- Generating precise toolpaths for machines

- Automating repetitive production tasks

- Minimizing errors in manufacturing

- Increasing consistency across batches

Tools like Mastercam, Fusion 360, and Edgecam bridge imagination and reality. Think about it: the gap between a brilliant design and a tangible product is now measured in software, not manual labor.

What is CAE? (Computer-Aided Engineering)

CAE takes things one step further. It asks, “Will this design survive real-world conditions?” By simulating stress, heat, vibration, and fluid flow, CAE predicts performance, safety, and durability before a single prototype exists.

Key Uses of CAE:

- Finite element analysis (FEA)

- Computational fluid dynamics (CFD)

- Thermal and structural simulations

- Optimizing designs for performance and safety

Popular tools like ANSYS, Abaqus, and COMSOL make it possible. Here’s a thought: Are we designing for reality—or for simulation? CAE challenges us to consider both.

CAD vs CAM vs CAE: A Simple Comparison

| Feature | CAD | CAM | CAE |

|---|---|---|---|

| Purpose | Design | Manufacturing | Analysis & Simulation |

| Focus | Product modeling | Machine programming | Product performance |

| Key Benefit | Visualization & precision | Efficient production | Safety & optimization |

| Example Tools | AutoCAD, SolidWorks | Mastercam, Fusion 360 | ANSYS, Abaqus |

Why Understanding the Difference Matters

Knowing the difference isn’t just academic. It transforms how products are conceived, produced, and perfected. Using CAD, CAM, and CAE effectively:

- Reduces time-to-market and material waste

- Enhances product reliability and innovation

- Enables seamless collaboration across disciplines

For those starting out, CAD courses are more than technical training—they’re a gateway to seeing design, manufacturing, and analysis as interconnected creative forces. Ask yourself: Which of these tools could change the way you think about problem-solving?

Conclusion

In essence: CAD designs, CAM builds, and CAE tests. Together, they form a triad that powers modern engineering innovation.

But here’s the bigger picture: as digital tools evolve, the question isn’t just “Which software should I use?”—it’s “How will I leverage these technologies to create something that wouldn’t exist otherwise?”

Investing in the right tools and honing skills through CAD courses isn’t just smart—it’s transformative. The future of engineering isn’t just automated—it’s imaginative, precise, and boundary-breaking.